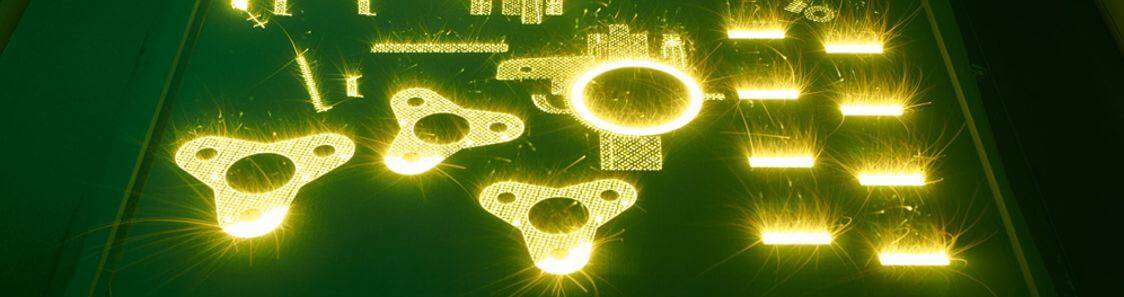

Selective Laser Melting

From the 3D-model straight to the functional part made from metal

Direct metal laser sintering is a technology with an extremely promising future. With this technique tool inserts and functional parts can be produced directly from 3D-data. This sophisticated, fast technique broadens the production of high-grade metal prototypes and supplements the precision metal casting technology.

An additive manufacturing technique, direct metal laser sintering works similar to the selective laser sintering with plastic – except for the base material in use. The first model is made from metal powder, which also is built up layer by layer using a laser. Prototypes created by metal laser sintering are used as mechanically robust functional parts, as well as quickly manufactured tool inserts. The metal powders in use are equivalent to the material used in serial productions and obtain 99.9% of their density and properties through the melting process.

Available materials

- aluminium (AlSi10Mg)

- stainless steel (1.4404)

- tool steel (1.2709)

- titanium (TiAl6V4)

- further material on request