Chronicle PTZ-Prototypenzentrum

2022

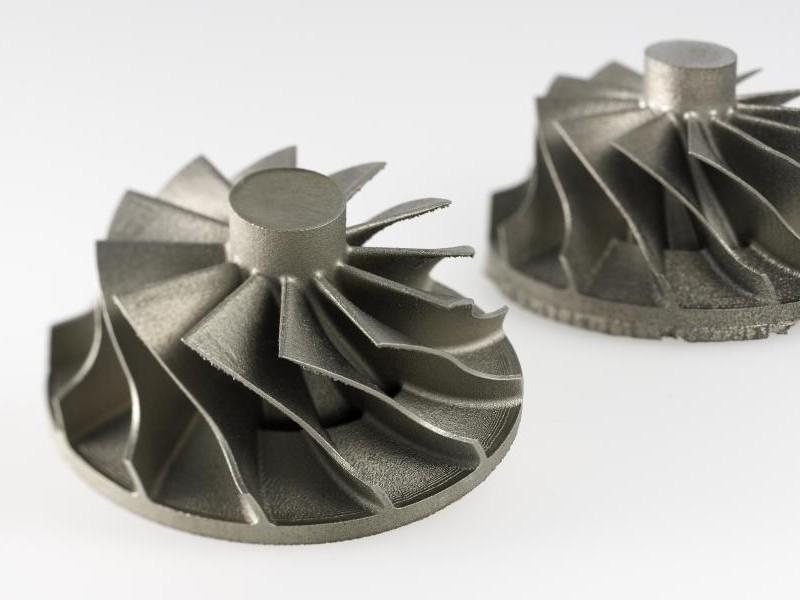

The increasing demand for components in Selective laser melting necessitated an expansion of capacity by adding another machine.

2019

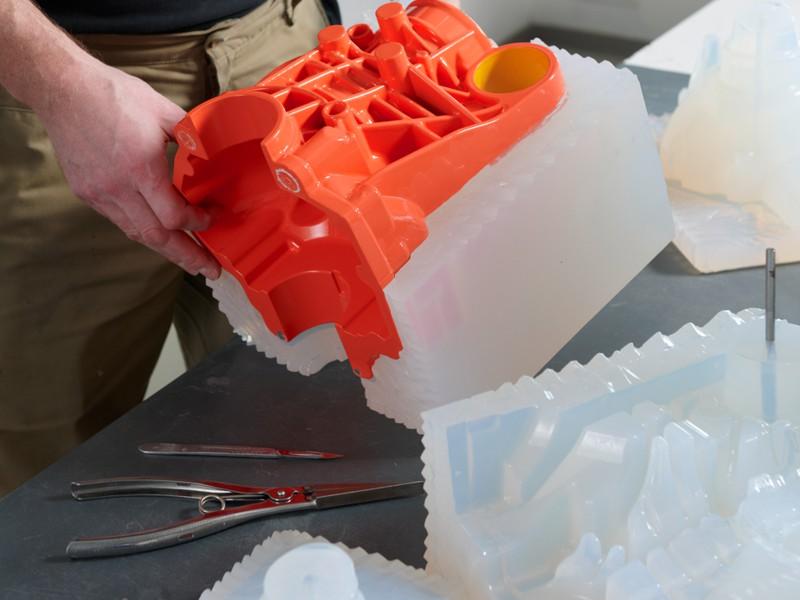

With new technology for polyamide casting, not only the capacity could be expanded. Increase of maximum usable space means a size of 1200 x 600 x 500 mm and a total part weight of up to 2.5 kg.

2015-2017

In autumn 2015, the construction of the new hall was started. After some difficulties, the hall was completed in March 2017. The moveof the vacuum casting department for both polyamide and polyurethane parts was in the way.

2013

Start of SLM 280 HL (Selective Laser Melting)build space: 280 x 280 x 350 mm

material: stainless steel, aluminium, tool steel, titanium

2004

Successful certification according to DIN EN ISO 9001

2001

Terms of the new production building Otto Mohr-Str. 15

2000

Transformation into PTZ prototype center GmbH

1997-1999

Manufacturing in Polyurethane casting , Lost wax casting (including wax models) and Stereolithography